Back

Beijing Ruituo Jiangnan Self-controlled Equipment Co., Ltd.

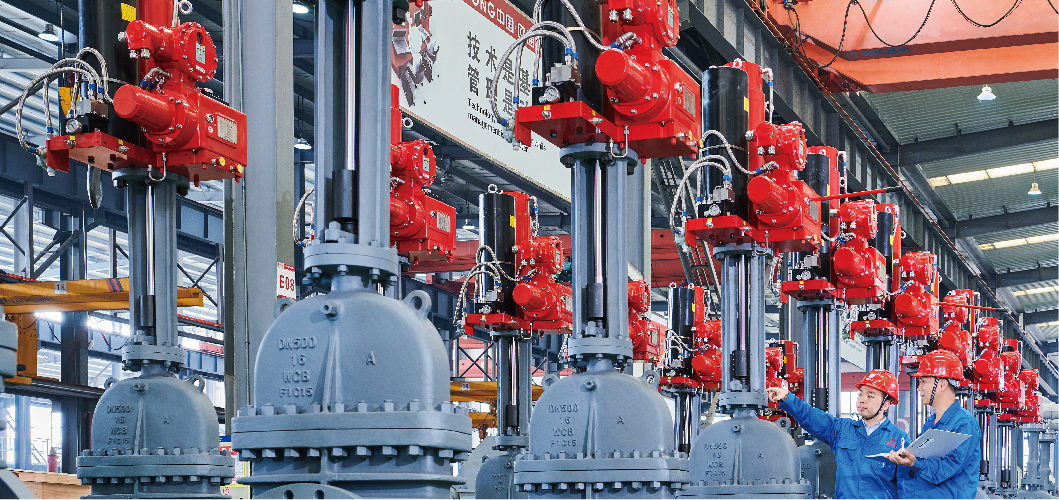

Adqvalve Flow Control Industry Group Limited is an international joint control valve enterprise group, specializing in the design, R&D and manufacture of angular travel control valves, in order to replace the traditional control valve and develop a new angle travel control valve. Ben. Adqvalve Group is a large-scale customized production model, using the technical products and materials of large-scale enterprises in the United States, Canada, Norway, Sweden, the United Kingdom, Germany, Italy, Asia-Pacific and other regions, using the national "close" factory to complete the product assembly, and achieve local technical support and speed. Service.

Beijing Ruituo Jiangnan Self-controlled Equipment Co., Ltd. (hereinafter referred to as Edwell? Ruituo) is an authorized manufacturer of Edwell Industrial Group in the Asia-Pacific region. It is mainly responsible for the introduction of Adqvalve international angle travel control valve technology and products, and carries out localized design and development, core manufacturing, assembly and technical support.

Edwell Ruito adopts the "customized manufacturing model" of Adqvalve Group, which is composed of the following four aspects: first, the standardization system for development, design, manufacturing, inspection and supervision of enterprises; second, the introduction of international advanced technologies and materials and processing methods; third, to achieve scale in the Asia-Pacific region. Customized manufacturing, complete the final assembly manufacturing and inspection of products in the "close" factory; Fourth, realize localized technical support and rapid service.

Edwell? Ruituo implements the enterprise quality standards of Adqvalve Group, which not only meets the standards of API, CE, GB and other institutions, but also mainly has its own technical and manufacturing requirements in various varieties of control valves, component structures, materials, processing and treatment. The product has 6 categories of butterfly control valves and 5 categories of ball control valves, and has obtained a number of international and domestic patents.

Among them, the "double fork, double piston, double spring integral cylinder" driven by the angular stroke 90°, is suitable for high-frequency secondary action conditions, safe reset conditions, harsh environmental conditions, and stable adjustment of working conditions.

Other products have their own key technical points: such as all-metal three-eccentric butterfly valve: the traditional metal butterfly valve sealing ring is composed of multi-layer steel sheet. The sealing ring is composed of all-metal hardened corrosion-resistant materials, which can achieve zero leakage sealing standard, strong wear resistance, long service life and wide range of use. Large-caliber metal sealed ball valve; another example: metal sealed ball valve adopts spray welding grinding technology and floating seat design. Soft seal butterfly valves, ball valves, and sealing components are made of specially manufactured sliding seal reinforcement materials. The product objectives are: to replace the traditional self-controlled gate valve, globe valve, ball valve and butterfly valve.

Edwell? Ruituo has been comprehensively studying the working conditions of users for more than 20 years. Most of the working conditions are flammable and explosive, and the conditions are harsh and harsh. We have been adhering to the implementation of Adqvalve Group's technical standards, completing targeted production and manufacturing, providing efficient control valves for many high-tech chemical enterprises, and bringing greater use prices to users. Value. In the future, we will further promote technological innovation and make unremitting efforts to deepen and improve the application value of products!

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='156.084mm'%20height='182.527mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20230.96%20270.09'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%235A5A5A}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M17.58%20125.97l0%20122.4c0,2.28%201.86,4.14%204.14,4.14l187.52%200c2.28,0%204.14,-1.86%204.14,-4.14l0%20-104.31%2017.58%200%200%20120.94c0,2.8%20-2.29,5.1%20-5.1,5.1l-220.77%200c-2.8,0%20-5.1,-2.29%20-5.1,-5.1l0%20-139.02%2017.58%200z'/%3e%3crect%20class='fil0'%20x='213.38'%20y='134.99'%20width='17.58'%20height='63.4'%20rx='16.71'%20ry='90.37'/%3e%3crect%20class='fil0'%20y='86.11'%20width='17.58'%20height='63.4'%20rx='16.71'%20ry='90.37'/%3e%3cpath%20class='fil0'%20d='M121.25%201.92l105.95%2084.9c3.77,3.02%204.39,8.58%201.36,12.36l0%200c-3.02,3.77%20-8.58,4.39%20-12.36,1.36l-105.95%20-84.9c-3.77,-3.02%20-4.39,-8.58%20-1.36,-12.36l0%200c3.02,-3.77%208.58,-4.39%2012.36,-1.36z'/%3e%3cpath%20class='fil0'%20d='M110.32%201.92l-105.95%2084.9c-3.77,3.02%20-4.39,8.58%20-1.36,12.36l0%200c3.02,3.77%208.58,4.39%2012.36,1.36l105.95%20-84.9c3.77,-3.02%204.39,-8.58%201.36,-12.36l0%200c-3.02,-3.77%20-8.58,-4.39%20-12.36,-1.36z'/%3e%3cpath%20class='fil0'%20d='M72.1%20209.89l17.58%200%200%2023.94c0,4.83%20-3.96,8.79%20-8.79,8.79l0%200c-4.83,0%20-8.79,-3.96%20-8.79,-8.79l0%20-23.94z'/%3e%3cpath%20class='fil0'%20d='M89.68%20230.01l0%20-40.7%2050.64%200%200%2071.8%2011.31%200c3.45,0%206.26,-2.82%206.26,-6.26l0%20-76.85c0,-3.45%20-2.82,-6.26%20-6.26,-6.26l-73.27%200c-3.45,0%20-6.26,2.82%20-6.26,6.26l0%2052.01%2017.58%200z'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='235.381mm'%20height='180.536mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20662.31%20507.99'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%235A5A5A}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M330.6%2073.45c67.01,0%20121.34,54.32%20121.34,121.34%200,67.01%20-54.32,121.34%20-121.34,121.34%20-67.01,0%20-121.34,-54.32%20-121.34,-121.34%200,-67.01%2054.32,-121.34%20121.34,-121.34zm0%2028.46c51.29,0%2092.88,41.58%2092.88,92.88%200,51.3%20-41.58,92.88%20-92.88,92.88%20-51.29,0%20-92.88,-41.58%20-92.88,-92.88%200,-51.29%2041.58,-92.88%2092.88,-92.88z'/%3e%3crect%20class='fil0'%20x='189.76'%20y='-0'%20width='281.67'%20height='23.86'%20rx='14.07'%20ry='16.18'/%3e%3cpolygon%20class='fil0'%20points='193.86,20.91%20288.51,80.97%20330.6,80.97%20229.01,16.88%20'/%3e%3cpolygon%20class='fil0'%20points='467.52,20.74%20372.88,80.97%20330.6,80.97%20428.1,16.88%20'/%3e%3cpath%20class='fil0'%20d='M67.35%20127.33l176.51%200c-9.18,9.74%20-16.74,13.88%20-22.25,26.28l-130.22%200c-6.63,0%20-12.06,5.43%20-12.06,12.06l0%20235.04%200%2029.13%200%2019.11%20-26.28%200%200%20-307.32c0,-7.86%206.43,-14.29%2014.29,-14.29zm349.99%200l176.51%200c7.86,0%2014.29,6.43%2014.29,14.29l0%20307.32%20-26.28%200%200%20-19.11%200%20-29.13%200%20-235.04c0,-6.63%20-5.43,-12.06%20-12.06,-12.06l-130.22%200c-5.51,-12.4%20-13.07,-16.54%20-22.25,-26.28z'/%3e%3cpath%20class='fil0'%20d='M154.76%20234.8l73.69%200c4.42,7.34%209.62,21.3%2015.46,27.5l-61.18%200c-4.43,0%20-8.05,3.3%20-8.05,7.34%200,58.93%200,117.87%200,176.8l-29.47%200%200%20-202.94c0,-4.79%204.3,-8.7%209.55,-8.7zm277.98%200l73.69%200c5.25,0%209.55,3.92%209.55,8.7l0%20202.94%20-29.47%200c0,-58.93%200,-117.87%200,-176.8%200,-4.04%20-3.63,-7.34%20-8.05,-7.34l-61.18%200c5.85,-6.19%2011.04,-20.16%2015.46,-27.5z'/%3e%3cpath%20class='fil0'%20d='M16.73%20434.14l185.74%200c9.2,0%2016.73,7.18%2016.73,15.95l0%2041.95c0,8.77%20-7.53,15.95%20-16.73,15.95l-185.74%200c-9.2,0%20-16.73,-7.18%20-16.73,-15.95l0%20-41.95c0,-8.77%207.53,-15.95%2016.73,-15.95zm4.18%2023.35l177.38%200%200%2027.16%20-177.38%200%200%20-27.16z'/%3e%3cpath%20class='fil0'%20d='M459.84%20434.14l185.74%200c9.2,0%2016.73,7.18%2016.73,15.95l0%2041.95c0,8.77%20-7.53,15.95%20-16.73,15.95l-185.74%200c-9.2,0%20-16.73,-7.18%20-16.73,-15.95l0%20-41.95c0,-8.77%207.53,-15.95%2016.73,-15.95zm4.18%2023.35l177.38%200%200%2027.16%20-177.38%200%200%20-27.16z'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='180.6mm'%20height='180.6mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20419.71%20419.71'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%235A5A5A}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M9.84%20140.52l147.39%200c5.41,0%209.84,4.43%209.84,9.84l0%20269.32%20-167.07%200%200%20-269.32c0,-5.41%204.43,-9.84%209.84,-9.84zm17.77%2027.79l111.85%200%200%20223.57%20-111.85%200%200%20-223.57z'/%3e%3cpath%20class='fil0'%20d='M149.3%200l260.57%200c5.41,0%209.84,4.43%209.84,9.84l0%20409.87%20-280.25%200%200%20-409.87c0,-5.41%204.43,-9.84%209.84,-9.84zm17.77%2028.33l225.03%200%200%20363.05%20-225.03%200%200%20-363.05z'/%3e%3crect%20class='fil0'%20x='223.66'%20y='97.63'%20width='28.04'%20height='28.04'%20rx='1.97'%20ry='1.97'/%3e%3crect%20class='fil0'%20x='307.53'%20y='97.63'%20width='28.04'%20height='28.04'%20rx='1.97'%20ry='1.97'/%3e%3crect%20class='fil0'%20x='223.66'%20y='181.81'%20width='28.04'%20height='28.04'%20rx='1.97'%20ry='1.97'/%3e%3crect%20class='fil0'%20x='307.53'%20y='181.81'%20width='28.04'%20height='28.04'%20rx='1.97'%20ry='1.97'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='156.084mm'%20height='182.527mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20230.96%20270.09'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%23C82127}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M17.58%20125.97l0%20122.4c0,2.28%201.86,4.14%204.14,4.14l187.52%200c2.28,0%204.14,-1.86%204.14,-4.14l0%20-104.31%2017.58%200%200%20120.94c0,2.8%20-2.29,5.1%20-5.1,5.1l-220.77%200c-2.8,0%20-5.1,-2.29%20-5.1,-5.1l0%20-139.02%2017.58%200z'/%3e%3crect%20class='fil0'%20x='213.38'%20y='134.99'%20width='17.58'%20height='63.4'%20rx='16.71'%20ry='90.37'/%3e%3crect%20class='fil0'%20y='86.11'%20width='17.58'%20height='63.4'%20rx='16.71'%20ry='90.37'/%3e%3cpath%20class='fil0'%20d='M121.25%201.92l105.95%2084.9c3.77,3.02%204.39,8.58%201.36,12.36l0%200c-3.02,3.77%20-8.58,4.39%20-12.36,1.36l-105.95%20-84.9c-3.77,-3.02%20-4.39,-8.58%20-1.36,-12.36l0%200c3.02,-3.77%208.58,-4.39%2012.36,-1.36z'/%3e%3cpath%20class='fil0'%20d='M110.32%201.92l-105.95%2084.9c-3.77,3.02%20-4.39,8.58%20-1.36,12.36l0%200c3.02,3.77%208.58,4.39%2012.36,1.36l105.95%20-84.9c3.77,-3.02%204.39,-8.58%201.36,-12.36l0%200c-3.02,-3.77%20-8.58,-4.39%20-12.36,-1.36z'/%3e%3cpath%20class='fil0'%20d='M72.1%20209.89l17.58%200%200%2023.94c0,4.83%20-3.96,8.79%20-8.79,8.79l0%200c-4.83,0%20-8.79,-3.96%20-8.79,-8.79l0%20-23.94z'/%3e%3cpath%20class='fil0'%20d='M89.68%20230.01l0%20-40.7%2050.64%200%200%2071.8%2011.31%200c3.45,0%206.26,-2.82%206.26,-6.26l0%20-76.85c0,-3.45%20-2.82,-6.26%20-6.26,-6.26l-73.27%200c-3.45,0%20-6.26,2.82%20-6.26,6.26l0%2052.01%2017.58%200z'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='235.381mm'%20height='180.536mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20662.31%20507.99'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%23C82127}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M330.6%2073.45c3.61,0%207.19,0.17%2010.72,0.48l76.17%20-50.06%20-177.41%200%2079.41%2050.1c3.66,-0.33%207.36,-0.51%2011.11,-0.51zm129.24%20360.69l26.66%200%200%20-164.5c0,-4.04%20-3.63,-7.34%20-8.05,-7.34l-47.02%200c-21.77,32.46%20-58.81,53.82%20-100.83,53.82%20-42.02,0%20-79.06,-21.36%20-100.83,-53.82l-47.02%200c-4.43,0%20-8.05,3.3%20-8.05,7.34l0%20164.5%2027.78%200c9.2,0%2016.73,7.18%2016.73,15.95l0%2041.95c0,8.77%20-7.53,15.95%20-16.73,15.95l-185.74%200c-9.2,0%20-16.73,-7.18%20-16.73,-15.95l0%20-41.95c0,-8.77%207.53,-15.95%2016.73,-15.95l36.33%200%200%20-292.51c0,-7.86%206.43,-14.29%2014.29,-14.29l162.38%200c14.11,-21.05%2034.62,-37.44%2058.76,-46.38l-91.55%20-58.09c-1.13,-0.49%20-2.17,-1.16%20-3.08,-1.96l-0%20-0%200%200c-2.51,-2.19%20-4.1,-5.41%20-4.1,-8.98l0%20-0c0,-6.56%205.37,-11.93%2011.93,-11.93l257.81%200c6.56,0%2011.93,5.37%2011.93,11.93l0%200c0,3.48%20-1.51,6.63%20-3.91,8.81%20-1.01,0.92%20-2.19,1.68%20-3.47,2.21l-91.17%2058.01%20-0.14%200c24.13,8.94%2044.63,25.32%2058.73,46.37l162.38%200c7.86,0%2014.29,6.43%2014.29,14.29l0%20292.51%2037.45%200c9.2,0%2016.73,7.18%2016.73,15.95l0%2041.95c0,8.77%20-7.53,15.95%20-16.73,15.95l-185.74%200c-9.2,0%20-16.73,-7.18%20-16.73,-15.95l0%20-41.95c0,-8.77%207.53,-15.95%2016.73,-15.95zm-129.24%20-332.24c51.29,0%2092.88,41.58%2092.88,92.88%200,51.3%20-41.58,92.88%20-92.88,92.88%20-51.29,0%20-92.88,-41.58%20-92.88,-92.88%200,-51.29%2041.58,-92.88%2092.88,-92.88z'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='256.296mm'%20height='179.965mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20720%20505.57'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%235A5A5A}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M67.46%20155.38l451.2%200c14.8,0%2026.91,12.11%2026.91,26.91l0%20296.36c0,14.8%20-12.11,26.91%20-26.91,26.91l-451.2%200c-14.8,0%20-26.91,-12.11%20-26.91,-26.91l0%20-296.36c0,-14.8%2012.11,-26.91%2026.91,-26.91zm19.93%2033.37l411.34%200c7.41,0%2013.47,6.06%2013.47,13.47l0%20256.5c0,7.41%20-6.06,13.47%20-13.47,13.47l-411.34%200c-7.41,0%20-13.47,-6.06%20-13.47,-13.47l0%20-256.5c0,-7.41%206.06,-13.47%2013.47,-13.47z'/%3e%3cpath%20class='fil0'%20d='M593.87%200l93.99%200c17.68,0%2032.14,18.25%2032.14,40.57l0%200c0,22.31%20-14.46,40.57%20-32.14,40.57l-93.99%200c-17.68,0%20-32.14,-18.25%20-32.14,-40.57l0%20-0c0,-22.31%2014.46,-40.57%2032.14,-40.57zm4.53%2014.48l84.92%200c11.37,0%2020.67,11.74%2020.67,26.08l0%200c0,14.35%20-9.3,26.09%20-20.67,26.09l-84.92%200c-11.37,0%20-20.67,-11.74%20-20.67,-26.09l0%200c0,-14.35%209.3,-26.08%2020.67,-26.08z'/%3e%3cpath%20class='fil0'%20d='M650.69%20224.47l-120.28%2055.35%200%2074.47%20125.12%2055.9c24.19,10.81%2033.15,-6.86%2033.15,-21.88l0%20-144.15c0,-14.3%20-16.21,-29.71%20-37.99,-19.69zm-6.43%2034.08l-84.15%2039.46%200.15%2039.9%2086.54%2038.24c12.84,5.67%2017.4,-3.82%2017.4,-12.17l0%20-94.47c0,-7.96%20-8.44,-16.35%20-19.94,-10.95z'/%3e%3cg%20id='_1707833857440'%3e%3cpath%20class='fil0'%20d='M195.52%20281.71c26.93,0%2048.77,21.83%2048.77,48.77%200,26.93%20-21.83,48.77%20-48.77,48.77%20-26.93,0%20-48.77,-21.83%20-48.77,-48.77%200,-26.93%2021.83,-48.77%2048.77,-48.77zm0%2019.89c15.95,0%2028.87,12.93%2028.87,28.87%200,15.95%20-12.93,28.87%20-28.87,28.87%20-15.95,0%20-28.87,-12.93%20-28.87,-28.87%200,-15.95%2012.93,-28.87%2028.87,-28.87z'/%3e%3cpath%20class='fil0'%20d='M390.59%20281.71c26.93,0%2048.77,21.83%2048.77,48.77%200,26.93%20-21.83,48.77%20-48.77,48.77%20-26.93,0%20-48.77,-21.83%20-48.77,-48.77%200,-26.93%2021.83,-48.77%2048.77,-48.77zm0%2019.89c15.95,0%2028.87,12.93%2028.87,28.87%200,15.95%20-12.93,28.87%20-28.87,28.87%20-15.95,0%20-28.87,-12.93%20-28.87,-28.87%200,-15.95%2012.93,-28.87%2028.87,-28.87z'/%3e%3crect%20class='fil0'%20x='197.21'%20y='281.72'%20width='193.38'%20height='18.57'/%3e%3c/g%3e%3cpath%20class='fil0'%20d='M480.37%20178.33l19.47%200%200%20-106.43c0,-10.47%208.56,-19.03%2019.03,-19.03l53.3%200%200%20-19.47%20-56.13%200c-19.62,0%20-35.68,16.05%20-35.68,35.68l0%20109.26z'/%3e%3cpath%20class='fil0'%20d='M360.58%20171.29l-19.47%200%200%20-66.59c0,-10.47%20-8.56,-19.03%20-19.03,-19.03l-322.07%200%200%20-19.47%20324.9%200c19.62,0%2035.68,16.06%2035.68,35.68l0%2069.42z'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='256.296mm'%20height='179.965mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20720%20505.57'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%23C82127}%20.fil1%20{fill:%23C82127}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M67.46%20155.38l451.2%200c14.8,0%2026.91,12.11%2026.91,26.91l0%20296.36c0,14.8%20-12.11,26.91%20-26.91,26.91l-451.2%200c-14.8,0%20-26.91,-12.11%20-26.91,-26.91l0%20-296.36c0,-14.8%2012.11,-26.91%2026.91,-26.91zm19.93%2033.37l411.34%200c7.41,0%2013.47,6.06%2013.47,13.47l0%20256.5c0,7.41%20-6.06,13.47%20-13.47,13.47l-411.34%200c-7.41,0%20-13.47,-6.06%20-13.47,-13.47l0%20-256.5c0,-7.41%206.06,-13.47%2013.47,-13.47z'/%3e%3cpath%20class='fil0'%20d='M593.87%200l93.99%200c17.68,0%2032.14,18.25%2032.14,40.57l0%200c0,22.31%20-14.46,40.57%20-32.14,40.57l-93.99%200c-17.68,0%20-32.14,-18.25%20-32.14,-40.57l0%20-0c0,-22.31%2014.46,-40.57%2032.14,-40.57zm4.53%2014.48l84.92%200c11.37,0%2020.67,11.74%2020.67,26.08l0%200c0,14.35%20-9.3,26.09%20-20.67,26.09l-84.92%200c-11.37,0%20-20.67,-11.74%20-20.67,-26.09l0%200c0,-14.35%209.3,-26.08%2020.67,-26.08z'/%3e%3cpath%20class='fil0'%20d='M650.69%20224.47l-120.28%2055.35%200%2074.47%20125.12%2055.9c24.19,10.81%2033.15,-6.86%2033.15,-21.88l0%20-144.15c0,-14.3%20-16.21,-29.71%20-37.99,-19.69zm-6.43%2034.08l-84.15%2039.46%200.15%2039.9%2086.54%2038.24c12.84,5.67%2017.4,-3.82%2017.4,-12.17l0%20-94.47c0,-7.96%20-8.44,-16.35%20-19.94,-10.95z'/%3e%3cpath%20class='fil0'%20d='M480.37%20178.33l19.47%200%200%20-106.43c0,-10.47%208.56,-19.03%2019.03,-19.03l53.3%200%200%20-19.47%20-56.13%200c-19.62,0%20-35.68,16.05%20-35.68,35.68l0%20109.26z'/%3e%3cpath%20class='fil0'%20d='M360.58%20171.29l-19.47%200%200%20-66.59c0,-10.47%20-8.56,-19.03%20-19.03,-19.03l-322.07%200%200%20-19.47%20324.9%200c19.62,0%2035.68,16.06%2035.68,35.68l0%2069.42z'/%3e%3cpath%20class='fil1'%20d='M55.97%20178.33l470.3%200%200%20306.77%20-470.3%200%200%20-306.77zm139.55%20103.38c0.56,0%201.13,0.01%201.69,0.03l0%20-0.02%20192.1%200c0.43,-0.01%200.86,-0.02%201.29,-0.02%2026.93,0%2048.77,21.83%2048.77,48.77%200,26.93%20-21.83,48.77%20-48.77,48.77%20-26.93,0%20-48.77,-21.83%20-48.77,-48.77%200,-11.39%203.91,-21.87%2010.45,-30.17l-118.45%200c6.55,8.3%2010.45,18.78%2010.45,30.17%200,26.93%20-21.83,48.77%20-48.77,48.77%20-26.93,0%20-48.77,-21.83%20-48.77,-48.77%200,-26.93%2021.83,-48.77%2048.77,-48.77zm195.07%2019.89c15.95,0%2028.87,12.93%2028.87,28.87%200,15.95%20-12.93,28.87%20-28.87,28.87%20-15.95,0%20-28.87,-12.93%20-28.87,-28.87%200,-15.95%2012.93,-28.87%2028.87,-28.87zm-195.07%200c15.95,0%2028.87,12.93%2028.87,28.87%200,15.95%20-12.93,28.87%20-28.87,28.87%20-15.95,0%20-28.87,-12.93%20-28.87,-28.87%200,-15.95%2012.93,-28.87%2028.87,-28.87z'/%3e%3cpath%20class='fil1'%20d='M545.57%20294.23c0,0%20108.6,-54.92%20118.71,-47.57%2010.11,7.35%2016.65,70.73%2016.65,70.73%200,0%203.57,74.95%20-7.14,76.14%20-10.7,1.19%20-101.61,-32.11%20-101.61,-32.11%200,0%20-30.99,-32.7%20-30.39,-36.87%200.59,-4.16%203.79,-30.33%203.79,-30.33z'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='180.6mm'%20height='180.6mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20419.71%20419.71'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%23C82127}%20.fil1%20{fill:%23C82127}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M9.84%20140.52l147.39%200c5.41,0%209.84,4.43%209.84,9.84l0%20269.32%20-167.07%200%200%20-269.32c0,-5.41%204.43,-9.84%209.84,-9.84zm17.77%2027.79l111.85%200%200%20223.57%20-111.85%200%200%20-223.57z'/%3e%3cpath%20class='fil0'%20d='M149.3%200l260.57%200c5.41,0%209.84,4.43%209.84,9.84l0%20409.87%20-280.25%200%200%20-409.87c0,-5.41%204.43,-9.84%209.84,-9.84zm17.77%2028.33l225.03%200%200%20363.05%20-225.03%200%200%20-363.05z'/%3e%3cpath%20class='fil1'%20d='M159.41%2020.67l238.92%200%200%20376.94%20-238.92%200%200%20-376.94zm66.21%2076.95l24.1%200c1.08,0%201.97,0.89%201.97,1.97l0%2024.1c0,1.08%20-0.89,1.97%20-1.97,1.97l-24.1%200c-1.08,0%20-1.97,-0.89%20-1.97,-1.97l0%20-24.1c0,-1.08%200.89,-1.97%201.97,-1.97zm83.87%2084.19l24.1%200c1.08,0%201.97,0.89%201.97,1.97l0%2024.1c0,1.08%20-0.89,1.97%20-1.97,1.97l-24.1%200c-1.08,0%20-1.97,-0.89%20-1.97,-1.97l0%20-24.1c0,-1.08%200.89,-1.97%201.97,-1.97zm-83.87%200l24.1%200c1.08,0%201.97,0.89%201.97,1.97l0%2024.1c0,1.08%20-0.89,1.97%20-1.97,1.97l-24.1%200c-1.08,0%20-1.97,-0.89%20-1.97,-1.97l0%20-24.1c0,-1.08%200.89,-1.97%201.97,-1.97zm83.87%20-84.19l24.1%200c1.08,0%201.97,0.89%201.97,1.97l0%2024.1c0,1.08%20-0.89,1.97%20-1.97,1.97l-24.1%200c-1.08,0%20-1.97,-0.89%20-1.97,-1.97l0%20-24.1c0,-1.08%200.89,-1.97%201.97,-1.97z'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='180.6mm'%20height='180.6mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20449.79%20449.79'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%235A5A5A}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M100.84%200l304.67%200c24.35,0%2044.28,19.93%2044.28,44.28l0%20361.23c0,24.36%20-19.93,44.28%20-44.28,44.28l-55%200%20-249.68%200%20-58.12%200c-23.5,0%20-42.72,-19.22%20-42.72,-42.72l0%20-293.93c0,-23.5%2019.22,-42.72%2042.72,-42.72l13.84%200%200%20-26.15c0,-24.36%2019.93,-44.28%2044.28,-44.28zm-14.69%20378.26c0,8.14%20-6.66,14.79%20-14.79,14.79%20-8.14,0%20-14.79,-6.66%20-14.79,-14.79l0%20-51.6%200%20-227.69%20-14.32%200c-6.96,0%20-12.65,5.69%20-12.65,12.65l0%20296.98c0,6.96%205.69,12.65%2012.65,12.65%20114.57,0%20239.17,0%20363.21,0%208.12,0%2014.76,-6.64%2014.76,-14.76l0%20-362.11c0,-8.12%20-6.64,-14.76%20-14.76,-14.76l-304.54%200c-8.12,0%20-14.76,6.64%20-14.76,14.76%200,94.09%200,188.19%200,282.28l0%2051.6z'/%3e%3cpath%20class='fil0'%20d='M125.13%2056.61l100.89%200c6.96,0%2012.65,5.69%2012.65,12.65l0%20100.89c0,6.96%20-5.69,12.65%20-12.65,12.65l-100.89%200c-6.96,0%20-12.65,-5.69%20-12.65,-12.65l0%20-100.89c0,-6.96%205.69,-12.65%2012.65,-12.65zm15.09%2027.74l70.71%200%200%2070.71%20-70.71%200%200%20-70.71z'/%3e%3crect%20class='fil0'%20x='267.07'%20y='84.35'%20width='126.19'%20height='14.23'%20rx='10.54'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='267.07'%20y='126'%20width='126.19'%20height='14.23'%20rx='10.54'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='267.07'%20y='167.65'%20width='126.19'%20height='14.23'%20rx='10.54'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='112.48'%20y='210.48'%20width='280.78'%20height='14.23'%20rx='23.46'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='112.48'%20y='252.39'%20width='280.78'%20height='14.23'%20rx='23.46'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='267.07'%20y='294.3'%20width='126.19'%20height='14.23'%20rx='10.54'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='267.07'%20y='336.67'%20width='126.19'%20height='14.23'%20rx='10.54'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='267.07'%20y='379.04'%20width='126.19'%20height='14.23'%20rx='10.54'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='112.48'%20y='294.3'%20width='126.19'%20height='14.23'%20rx='10.54'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='112.48'%20y='336.67'%20width='126.19'%20height='14.23'%20rx='10.54'%20ry='10.54'/%3e%3crect%20class='fil0'%20x='112.48'%20y='379.04'%20width='126.19'%20height='14.23'%20rx='10.54'%20ry='10.54'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='180.6mm'%20height='180.6mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20449.79%20449.79'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%23C82127}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M100.84%200l304.67%200c24.35,0%2044.28,19.93%2044.28,44.28l0%20361.23c0,24.36%20-19.93,44.28%20-44.28,44.28l-55%200%20-249.68%200%20-58.12%200c-23.5,0%20-42.72,-19.22%20-42.72,-42.72l0%20-293.93c0,-23.5%2019.22,-42.72%2042.72,-42.72l13.84%200%200%20-26.15c0,-24.36%2019.93,-44.28%2044.28,-44.28zm24.29%2056.61l100.89%200c6.96,0%2012.65,5.69%2012.65,12.65l0%20100.89c0,6.96%20-5.69,12.65%20-12.65,12.65l-100.89%200c-6.96,0%20-12.65,-5.69%20-12.65,-12.65l0%20-100.89c0,-6.96%205.69,-12.65%2012.65,-12.65zm-5.54%20322.43l111.96%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-111.96%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm0%20-42.37l111.96%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-111.96%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm0%20-42.37l111.96%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-111.96%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm154.59%2084.74l111.96%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-111.96%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm0%20-42.37l111.96%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-111.96%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm0%20-42.37l111.96%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-111.96%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm-154.59%20-41.91l266.55%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-266.55%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm0%20-41.91l266.55%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-266.55%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm154.59%20-42.83l111.96%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-111.96%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm0%20-41.65l111.96%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-111.96%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm0%20-41.65l111.96%200c3.91,0%207.12,3.2%207.12,7.12l0%200c0,3.91%20-3.2,7.12%20-7.12,7.12l-111.96%200c-3.91,0%20-7.12,-3.2%20-7.12,-7.12l0%200c0,-3.91%203.2,-7.12%207.12,-7.12zm-133.97%200l70.71%200%200%2070.71%20-70.71%200%200%20-70.71zm-83.66%20336.9l0%20-42.99%200%20-279.29%20-14.32%200c-6.96,0%20-12.65,5.69%20-12.65,12.65l0%20296.98c0,6.96%205.69,12.65%2012.65,12.65l14.32%200z'/%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='299.575mm'%20height='185.249mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20907.22%20561'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%235A5A5A}%20.fil1%20{fill:%235A5A5A;fill-rule:nonzero}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M454.55%200c15.37,0%2030.35,1.65%2044.79,4.76l0%2033.81c0,1.98%20-1.62,3.59%20-3.59,3.59l-82.4%200c-1.98,0%20-3.59,-1.62%20-3.59,-3.59l0%20-33.81c14.44,-3.11%2029.42,-4.76%2044.79,-4.76z'/%3e%3cpath%20class='fil0'%20d='M524.13%2011.7c82.93,28.8%20142.47,107.62%20142.47,200.36%200,117.11%20-94.94,212.05%20-212.05,212.05%20-117.11,0%20-212.05,-94.94%20-212.05,-212.05%200,-92.74%2059.54,-171.56%20142.47,-200.36l0%2025.49c0,17.13%2014.01,31.14%2031.14,31.14l76.9%200c17.13,0%2031.14,-14.01%2031.14,-31.14l0%20-25.49zm-69.59%2093.98c66.95,0%20121.23,54.28%20121.23,121.23%200,66.95%20-54.28,121.23%20-121.23,121.23%20-66.95,0%20-121.23,-54.28%20-121.23,-121.23%200,-66.95%2054.28,-121.23%20121.23,-121.23z'/%3e%3cpath%20class='fil0'%20d='M454.55%20131.16c52.88,0%2095.75,42.87%2095.75,95.75%200,52.88%20-42.87,95.75%20-95.75,95.75%20-52.88,0%20-95.75,-42.87%20-95.75,-95.75%200,-52.88%2042.87,-95.75%2095.75,-95.75zm0%2027.89c37.48,0%2067.86,30.38%2067.86,67.86%200,37.48%20-30.38,67.86%20-67.86,67.86%20-37.48,0%20-67.86,-30.38%20-67.86,-67.86%200,-37.48%2030.38,-67.86%2067.86,-67.86z'/%3e%3ccircle%20class='fil0'%20cx='454.55'%20cy='226.91'%20r='42.01'/%3e%3cg%3e%3cpath%20class='fil1'%20d='M213.26%20240.69c5.65,-1.27%2011.41,1.65%2012.88,6.53%201.47,4.88%20-1.91,9.86%20-7.56,11.13l-5.33%20-17.66zm240.34%20252.88l1.88%2018.18%20-25.87%201.4%20-26.66%200.32%20-27.25%20-0.71%20-27.65%20-1.69%20-27.87%20-2.63%20-27.89%20-3.51%20-27.72%20-4.35%20-27.36%20-5.15%20-26.81%20-5.9%20-26.06%20-6.6%20-25.13%20-7.27%20-24%20-7.89%20-22.69%20-8.48%20-21.19%20-9.03%20-19.5%20-9.55%20-17.63%20-10.06%20-15.58%20-10.57%20-13.34%20-11.09%20-10.88%20-11.67%20-8.12%20-12.3%20-4.97%20-12.96%20-1.33%20-13.45%202.68%20-13.57%206.74%20-13.27%2010.69%20-12.77%2014.59%20-12.27%2018.59%20-11.86%2022.77%20-11.5%2027.16%20-11.18%2031.77%20-10.85%2036.61%20-10.52%2041.66%20-10.15%205.33%2017.66%20-40.81%209.94%20-35.6%2010.22%20-30.57%2010.44%20-25.72%2010.58%20-21.05%2010.63%20-16.56%2010.55%20-12.28%2010.32%20-8.32%209.92%20-4.79%209.42%20-1.78%209.02%200.9%208.95%203.54%209.18%206.27%209.46%209.01%209.64%2011.63%209.66%2014.08%209.54%2016.33%209.31%2018.36%208.99%2020.17%208.59%2021.77%208.13%2023.16%207.61%2024.34%207.04%2025.32%206.41%2026.08%205.74%2026.64%205.01%2027%204.24%2027.15%203.42%2027.09%202.56%2026.83%201.64%2026.36%200.69%2025.68%20-0.31%2024.79%20-1.34zm20.62%2015.25l-11.09%20-14.51%201.18%2015.28%20-75.46%20-41.04%208.73%20-16.05%2075.46%2041.04%201.18%2015.28zm0%200l-1.18%20-15.28%2012.37%206.73%20-11.19%208.55zm-73.82%2044.91l-5.55%20-7.26%2068.27%20-52.17%2011.09%2014.51%20-68.27%2052.17%20-5.55%20-7.26zm53.2%20-60.17c5.81,-0.45%2010.94,3.26%2011.46,8.28%200.52,5.02%20-3.77,9.45%20-9.58,9.9l-1.88%20-18.18z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='fil1'%20d='M695.83%20240.69l-5.33%2017.66c-5.65,-1.27%20-9.03,-6.25%20-7.56,-11.13%201.47,-4.88%207.24,-7.8%2012.88,-6.53zm-152.36%20252.07l24.74%20-0.45%2024.76%20-1.34%2024.65%20-2.18%2024.4%20-2.98%2024.01%20-3.74%2023.48%20-4.45%2022.82%20-5.13%2022.02%20-5.75%2021.08%20-6.34%2020%20-6.87%2018.78%20-7.36%2017.42%20-7.8%2015.91%20-8.17%2014.26%20-8.49%2012.48%20-8.73%2010.56%20-8.88%208.52%20-8.94%206.4%20-8.89%204.26%20-8.76%202.14%20-8.59%200.05%20-8.52%20-2.13%20-8.63%20-4.55%20-8.91%20-7.3%20-9.24%20-10.33%20-9.52%20-13.58%20-9.68%20-17.01%20-9.72%20-20.56%20-9.67%20-24.24%20-9.54%20-28.04%20-9.33%20-31.96%20-9.06%20-36%20-8.74%205.33%20-17.66%2036.81%208.94%2032.89%209.33%2029.12%209.69%2025.49%2010.03%2022.01%2010.36%2018.67%2010.68%2015.47%2011.02%2012.36%2011.39%209.3%2011.79%206.21%2012.17%203.06%2012.41%20-0.06%2012.4%20-3%2012.12%20-5.65%2011.67%20-8.01%2011.15%20-10.13%2010.65%20-12.07%2010.17%20-13.86%209.7%20-15.51%209.23%20-17.04%208.76%20-18.45%208.26%20-19.73%207.74%20-20.89%207.18%20-21.92%206.59%20-22.83%205.97%20-23.62%205.3%20-24.27%204.6%20-24.8%203.86%20-25.2%203.07%20-25.47%202.25%20-25.61%201.38%20-25.62%200.47%200%20-18.25zm0%200l0%2018.25c-5.83,0%20-10.56,-4.09%20-10.56,-9.12%200,-5.04%204.73,-9.12%2010.56,-9.12z'/%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

%20--%3e%3csvg%20xmlns='http://www.w3.org/2000/svg'%20xml:space='preserve'%20width='299.575mm'%20height='185.249mm'%20version='1.1'%20style='shape-rendering:geometricPrecision;%20text-rendering:geometricPrecision;%20image-rendering:optimizeQuality;%20fill-rule:evenodd;%20clip-rule:evenodd'%20viewBox='0%200%20907.22%20561'%20xmlns:xlink='http://www.w3.org/1999/xlink'%3e%3cdefs%3e%3cstyle%20type='text/css'%3e%3c![CDATA[%20.fil0%20{fill:%23C82127}%20.fil1%20{fill:%23C82127;fill-rule:nonzero}%20]]%3e%3c/style%3e%3c/defs%3e%3cg%20id='图层_x0020_1'%3e%3cmetadata%20id='CorelCorpID_0Corel-Layer'/%3e%3cpath%20class='fil0'%20d='M454.55%200c15.37,0%2030.35,1.65%2044.79,4.76l0%2033.81c0,1.98%20-1.62,3.59%20-3.59,3.59l-82.4%200c-1.98,0%20-3.59,-1.62%20-3.59,-3.59l0%20-33.81c14.44,-3.11%2029.42,-4.76%2044.79,-4.76z'/%3e%3cpath%20class='fil0'%20d='M524.13%2011.7c82.93,28.8%20142.47,107.62%20142.47,200.36%200,117.11%20-94.94,212.05%20-212.05,212.05%20-117.11,0%20-212.05,-94.94%20-212.05,-212.05%200,-92.74%2059.54,-171.56%20142.47,-200.36l0%2025.49c0,17.13%2014.01,31.14%2031.14,31.14l76.9%200c17.13,0%2031.14,-14.01%2031.14,-31.14l0%20-25.49zm-69.59%2093.98c66.95,0%20121.23,54.28%20121.23,121.23%200,66.95%20-54.28,121.23%20-121.23,121.23%20-66.95,0%20-121.23,-54.28%20-121.23,-121.23%200,-66.95%2054.28,-121.23%20121.23,-121.23z'/%3e%3cpath%20class='fil0'%20d='M454.55%20131.16c52.88,0%2095.75,42.87%2095.75,95.75%200,52.88%20-42.87,95.75%20-95.75,95.75%20-52.88,0%20-95.75,-42.87%20-95.75,-95.75%200,-52.88%2042.87,-95.75%2095.75,-95.75zm0%2027.89c37.48,0%2067.86,30.38%2067.86,67.86%200,37.48%20-30.38,67.86%20-67.86,67.86%20-37.48,0%20-67.86,-30.38%20-67.86,-67.86%200,-37.48%2030.38,-67.86%2067.86,-67.86z'/%3e%3ccircle%20class='fil0'%20cx='454.55'%20cy='226.91'%20r='42.01'/%3e%3cg%3e%3cpath%20class='fil1'%20d='M213.26%20240.69c5.65,-1.27%2011.41,1.65%2012.88,6.53%201.47,4.88%20-1.91,9.86%20-7.56,11.13l-5.33%20-17.66zm240.34%20252.88l1.88%2018.18%20-25.87%201.4%20-26.66%200.32%20-27.25%20-0.71%20-27.65%20-1.69%20-27.87%20-2.63%20-27.89%20-3.51%20-27.72%20-4.35%20-27.36%20-5.15%20-26.81%20-5.9%20-26.06%20-6.6%20-25.13%20-7.27%20-24%20-7.89%20-22.69%20-8.48%20-21.19%20-9.03%20-19.5%20-9.55%20-17.63%20-10.06%20-15.58%20-10.57%20-13.34%20-11.09%20-10.88%20-11.67%20-8.12%20-12.3%20-4.97%20-12.96%20-1.33%20-13.45%202.68%20-13.57%206.74%20-13.27%2010.69%20-12.77%2014.59%20-12.27%2018.59%20-11.86%2022.77%20-11.5%2027.16%20-11.18%2031.77%20-10.85%2036.61%20-10.52%2041.66%20-10.15%205.33%2017.66%20-40.81%209.94%20-35.6%2010.22%20-30.57%2010.44%20-25.72%2010.58%20-21.05%2010.63%20-16.56%2010.55%20-12.28%2010.32%20-8.32%209.92%20-4.79%209.42%20-1.78%209.02%200.9%208.95%203.54%209.18%206.27%209.46%209.01%209.64%2011.63%209.66%2014.08%209.54%2016.33%209.31%2018.36%208.99%2020.17%208.59%2021.77%208.13%2023.16%207.61%2024.34%207.04%2025.32%206.41%2026.08%205.74%2026.64%205.01%2027%204.24%2027.15%203.42%2027.09%202.56%2026.83%201.64%2026.36%200.69%2025.68%20-0.31%2024.79%20-1.34zm20.62%2015.25l-11.09%20-14.51%201.18%2015.28%20-75.46%20-41.04%208.73%20-16.05%2075.46%2041.04%201.18%2015.28zm0%200l-1.18%20-15.28%2012.37%206.73%20-11.19%208.55zm-73.82%2044.91l-5.55%20-7.26%2068.27%20-52.17%2011.09%2014.51%20-68.27%2052.17%20-5.55%20-7.26zm53.2%20-60.17c5.81,-0.45%2010.94,3.26%2011.46,8.28%200.52,5.02%20-3.77,9.45%20-9.58,9.9l-1.88%20-18.18z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='fil1'%20d='M695.83%20240.69l-5.33%2017.66c-5.65,-1.27%20-9.03,-6.25%20-7.56,-11.13%201.47,-4.88%207.24,-7.8%2012.88,-6.53zm-152.36%20252.07l24.74%20-0.45%2024.76%20-1.34%2024.65%20-2.18%2024.4%20-2.98%2024.01%20-3.74%2023.48%20-4.45%2022.82%20-5.13%2022.02%20-5.75%2021.08%20-6.34%2020%20-6.87%2018.78%20-7.36%2017.42%20-7.8%2015.91%20-8.17%2014.26%20-8.49%2012.48%20-8.73%2010.56%20-8.88%208.52%20-8.94%206.4%20-8.89%204.26%20-8.76%202.14%20-8.59%200.05%20-8.52%20-2.13%20-8.63%20-4.55%20-8.91%20-7.3%20-9.24%20-10.33%20-9.52%20-13.58%20-9.68%20-17.01%20-9.72%20-20.56%20-9.67%20-24.24%20-9.54%20-28.04%20-9.33%20-31.96%20-9.06%20-36%20-8.74%205.33%20-17.66%2036.81%208.94%2032.89%209.33%2029.12%209.69%2025.49%2010.03%2022.01%2010.36%2018.67%2010.68%2015.47%2011.02%2012.36%2011.39%209.3%2011.79%206.21%2012.17%203.06%2012.41%20-0.06%2012.4%20-3%2012.12%20-5.65%2011.67%20-8.01%2011.15%20-10.13%2010.65%20-12.07%2010.17%20-13.86%209.7%20-15.51%209.23%20-17.04%208.76%20-18.45%208.26%20-19.73%207.74%20-20.89%207.18%20-21.92%206.59%20-22.83%205.97%20-23.62%205.3%20-24.27%204.6%20-24.8%203.86%20-25.2%203.07%20-25.47%202.25%20-25.61%201.38%20-25.62%200.47%200%20-18.25zm0%200l0%2018.25c-5.83,0%20-10.56,-4.09%20-10.56,-9.12%200,-5.04%204.73,-9.12%2010.56,-9.12z'/%3e%3c/g%3e%3c/g%3e%3c/svg%3e)