Dn150 Pn160 09g2s Cast Steel Turbine Operation Metal Seat Fixed Ball Valve

Collect

Manufacturer

Product Parameters

Product Features

Product Features

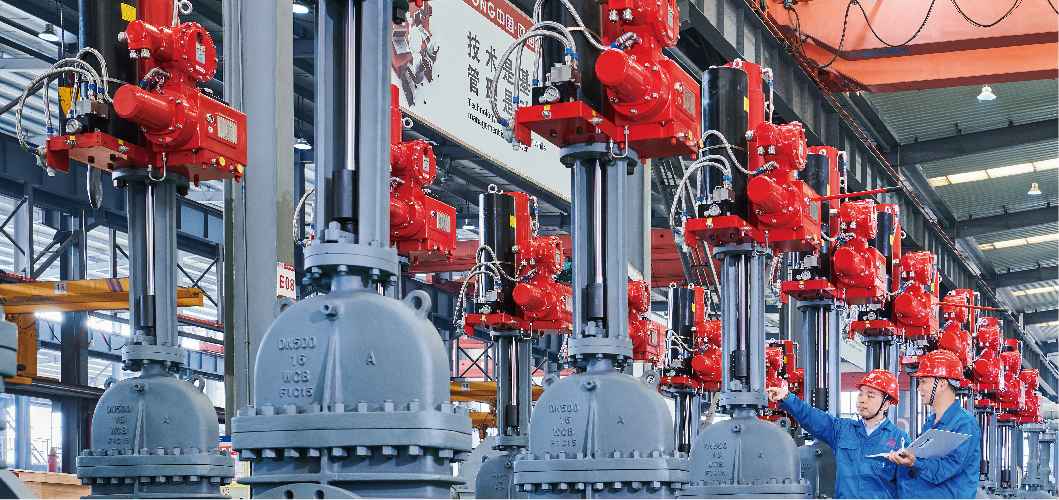

The DiDe double resistance double ball valve is designed for use in the harsh environment of the oil and gas industry, including production, transportation, and distribution processes.

The Dide casting fixed ball valve is designed as a side entry fixed ball valve, with two independent floating valve seats to ensure bidirectional sealing of the valve. The design of this valve seat reduces the torque required to operate the valve without reducing the sealing force. Sealing force is achieved by zero pressure difference to the maximum rated pressure of the valve. In addition, these repairable valves can achieve simultaneous sealing of both valve seats, and when the ball is in the closed state, the pressure entering the ball cavity can be slowly released. The characteristic of double resistance and double row can be used to verify the complete sealing of the valve seat.

Product Details

Product Details

The DiDe double resistance double ball valve is designed for use in the harsh environment of the oil and gas industry, including production, transportation, and distribution processes.

The Dide casting fixed ball valve is designed as a side entry fixed ball valve, with two independent floating valve seats to ensure bidirectional sealing of the valve. The design of this valve seat reduces the torque required to operate the valve without reducing the sealing force. Sealing force is achieved by zero pressure difference to the maximum rated pressure of the valve. In addition, these repairable valves can achieve simultaneous sealing of both valve seats, and when the ball is in the closed state, the pressure entering the ball cavity can be slowly released. The characteristic of double resistance and double row can be used to verify the complete sealing of the valve seat.

Manufacturer

Didtek Valve Group Co., Ltd.